Random micropatterns of fluorescent molecules in sugar films could protect drugs from counterfeiting, for example

Counterfeit products could be detected more reliably in the future than has been the case up to now. A team from the Max Planck Institute of Colloids and Interfaces has developed a method to protect products such as medicines or electronic components from counterfeiting with inexpensive, non-copyable fluorescent markings. The researchers use a laser to create fluorescent molecules in sugar films in random patterns. In order to prevent counterfeit products from spreading, a medicine pack could be provided with one of the individual patterns. A pharmacy could then compare the pattern with a photo taken during production and stored in a database.

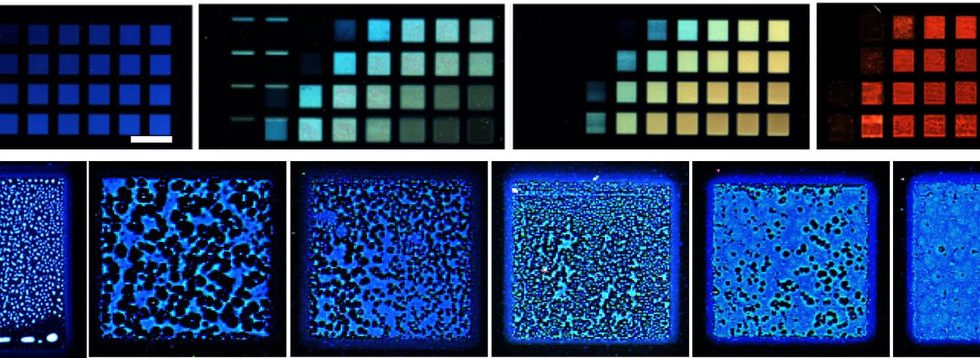

© Nature Nanotechnology 2023/Felix Löffler Control and coincidence: The overall color impression of luminous patterns that are created in layers of sugar with a laser can be controlled with the help of artificial intelligence (top row). In contrast, the micropatterns of the fluorescent molecules are completely random (bottom row). © Nature Nanotechnology 2023/Felix Löffler

Counterfeit medicines are a health hazard. Sometimes they don’t have the desired effect, and often they even do harm. According to the World Health Organization (WHO), around 50 percent of medicines purchased from unauthorized online retailers are counterfeit. Drug piracy also causes massive economic damage. According to estimates by the EU status report on rights violations (Equipo, 2019), the European pharmaceutical industry lost around 9.6 billion euros in sales annually due to counterfeit medicines. To counter this, drug packaging has been provided with QR codes across the EU since 2019, but these only provide limited copy protection. More sophisticated security features such as fluorescent holograms printed on banknotes typically contain toxic inorganic substances. And once the fluorescent compounds have been identified, it only takes about 18 months on average before they are copied.

A team led by Felix Löffler, group leader at the Max Planck Institute of Colloids and Interfaces, therefore presents a new approach for non-copyable security features in a publication in the journal Nature Nanotechnology, which could protect not only medicines but also electronic components from piracy . The researchers shoot a thin film of sugar, consisting of simple monosaccharides, with a laser. In this lightning synthesis, the sugar caramelizes in milliseconds and compounds are formed that fluoresce in different colors. It is not possible to predict which substances are produced in detail. However, the researchers can use a variety of parameters, such as the strength and duration of the laser flashes and additives in the sugar film, to control which color impression the pattern should produce as a whole. “Depending on the laser parameters and additives, the patterns under the scanner fluoresce in unique color gradations of red, green or blue,” says Felix Löffler. In order to predict the macroscopic color effect, the researchers trained an artificial intelligence, i.e. a machine learning algorithm, with a large number of experimental examples.

Random microstructures make the patterns counterfeit-proof

However, the overall color impression is of secondary importance for effective copy protection. In order to be able to use the fluorescent sugar layer as a security feature, the details of the pattern on a microscopic level are important, i.e. the type and arrangement of the individual luminous dots that are generated by the laser bombardment. “The resulting micro- and nanostructures are completely random and make the pattern tamper-proof,” says Junfang Zhang, who played a key role in the study. In its experiments, the team created a sugar film library with around 2,000 nanopatterns. As soon as a drug packaging or an electronic component is provided with a desired macroscopic pattern, but a completely random nano- and micro-pattern, a high-resolution photo of the fluorescence pattern could be stored in a database. Using the image, intermediaries or pharmacies could then use a fluorescence scan to check whether a drug is an original product.

In addition to the nano and micro pattern of the colored luminous dots, the height profile of the sugar film, which is created during caramelization with a laser, can be used as a further security feature. “Each sugar pattern has a unique topography,” says Felix Löffler. This can also be recorded and compared with topography scans both during production and at dealerships. The combination of fluorescence pattern and topography significantly increases counterfeit security. “With our process, we can do up to 1063000 produce different variants on a square millimeter,” says Felix Löffler. 1063000 corresponds to a 1 followed by 63000 zeros. For comparison: the number of atoms in the universe is about 1089.

JJ/PH