Technology: Batteries of tomorrow

It depends on the density

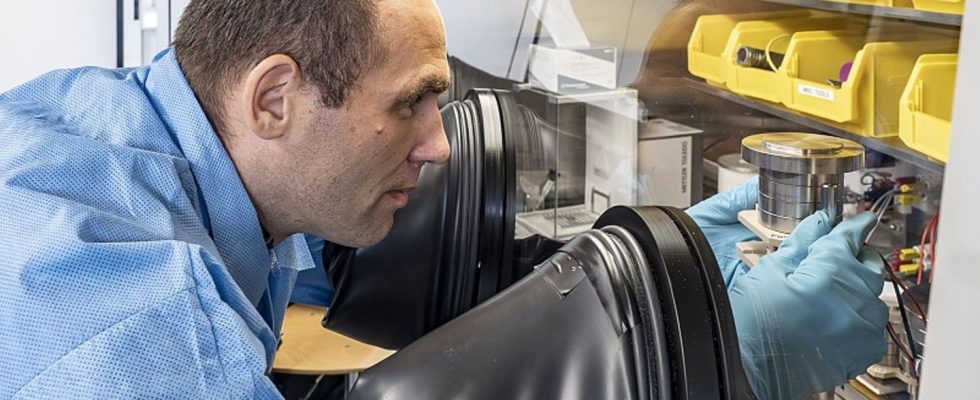

Kostiantyn Kravchyk is researching new batteries at Empa

© press-inform – the press office

When it comes to the battery of the future, it depends on the intended use. Batteries with high energy density are desired, but are more expensive. Cheap batteries are important for energy storage. Researchers are working hard on the batteries of tomorrow.

There is always talk of miracle batteries that promise impressive ranges and charging speeds. But the reality is different. The electrochemistry is much more difficult than the announcement paper is patient. A good example are solid-state batteries, which, if one were to believe the forecasts and promises of various car and commercial vehicle manufacturers, should have already become part of everyday life. Instead they will Lithium-ion batteries will continue to form the backbone of the power supply for electric vehicles for quite some time. In order to find the Columbus egg of electromobility, the researchers have to reconcile many parameters. A big challenge. This already begins with defining the specifications for the electricity storage system.

It depends on the density

What is important about the battery? The capacity, i.e. the range, for long-distance vehicles? Load quickly? Or that it is cheap? This is the case with small cars or with stationary energy storage systems. The technicians’ job is to find the perfect battery composition for every application. Every battery consists of a cathode, an anode and the electrolyte that conducts the ions from the cathode to the anode or vice versa. Depending on whether the cell is currently being charged or discharged. So far, so clear. But now the tinkering begins. In order to obtain batteries that are as compact as possible and are generally also lighter, the energy density should be increased, which promises more range in the same installation space.

“With an anode made of pure metallic lithium instead of graphite, we could store many times more energy in a cell of the same size,” explains Kostiantyn Kravchyk, who is researching the batteries of tomorrow at Empa (Federal Materials Testing and Research Institute). This would mean the jackpot for electromobility has been found. Goodbye range anxiety! Not so fast! When charging and discharging the battery, the lithium is not added and removed evenly. The consequence is not very pleasant. So-called dendrites form, i.e. branched structures made of metallic lithium, which can cause a short circuit.

A solid electrolyte, such as that used in solid-state batteries, significantly slows the growth of dendrites. But now fast charging comes into play. If you want batteries to provide energy in ten to fifteen minutes, you need a high current density (ratio of the current strength to the area through which the current flows), which causes dendrites to form even in solid-state batteries. On top of that. Due to the resulting uneven removal and application of lithium, cavities form at the boundary between the electrode and the solid electrolyte, which reduce the available area and increase the current density even further and thus the risk of dendrite proliferation. A vicious circle.

The solution to this dilemma could be a solid electrolyte made of lithium lanthanum zirconium oxide (LLZO), which has high ionic conductivity and chemical stability – ideal properties for use in batteries. “We processed LLZO into a two-layer membrane that consists of a dense and a porous layer,” explains Kravchyk. This structure already represents part of the solution. If lithium is stored in the pores, a very large contact area is created between the lithium and the electrolyte and the current density remains low. The dense layer also prevents dendrites from growing towards the other electrode. The best comes last: The researchers have developed a simple and cost-effective process to produce these two-layer membranes.

But that is not the only area of the energy transition that the researchers have in their sights. In order to manage electricity requirements, as many stationary storage devices as possible are necessary. These can be “second life” batteries, i.e. discarded batteries from electric cars. But their expensive and rare raw materials can be reused through increasingly sophisticated recycling processes. The researchers’ task is to develop the cheapest possible stationary storage systems that can be used on a large scale and thus gradually replace the relatively inefficient pumped storage power plants, which have a very low energy density compared to batteries.

The key to this challenge is the materials. In lithium-ion batteries, the cathode is made of cobalt and nickel. What if you used iron instead, which is significantly cheaper? So the engineers combine the cathode with iron(III) hydroxyfluoride. The catch is that fluorides have poor conductivity for electrons and lithium ions. The solution is simple and not expensive. The researchers put the iron(III) hydroxyfluoride into a special crystal structure. This so-called pyrochlore structure contains passages inside that conduct lithium ions. “We were able to achieve comparable performance with our battery at a significantly lower price,” says Kravchyk happily, adding: “We are surprised that so far hardly anyone has researched how this promising material could be produced cost-effectively.” Sounds promising. Now these batteries just have to pass the everyday test.