Natural raw materials

Steak knives made from super wood three times as sharp as steel knives

Sharper than stainless steel and yet the knife is made of wood.

© PR

Maryland scientists want to improve wood so that it can replace steel and ceramics. They create a naturally growing material that is stronger than steel.

Wood can be the material of the future. Ultimately, it is available in unlimited quantities, it grows back and the best thing about it: Wood removes the climate gas CO2 from the atmosphere. A forest is the natural and cheap variant of a high-tech CO2 absorber. Scientists at the University of Maryland are working to improve the natural properties of wood. So that wood can replace materials such as steel or concrete without restricting their function. Now they have achieved another breakthrough with their super wood. In a new study, they describe how they were able to harden wood so that knives and nails can be made with the material.

Redensification of the natural material

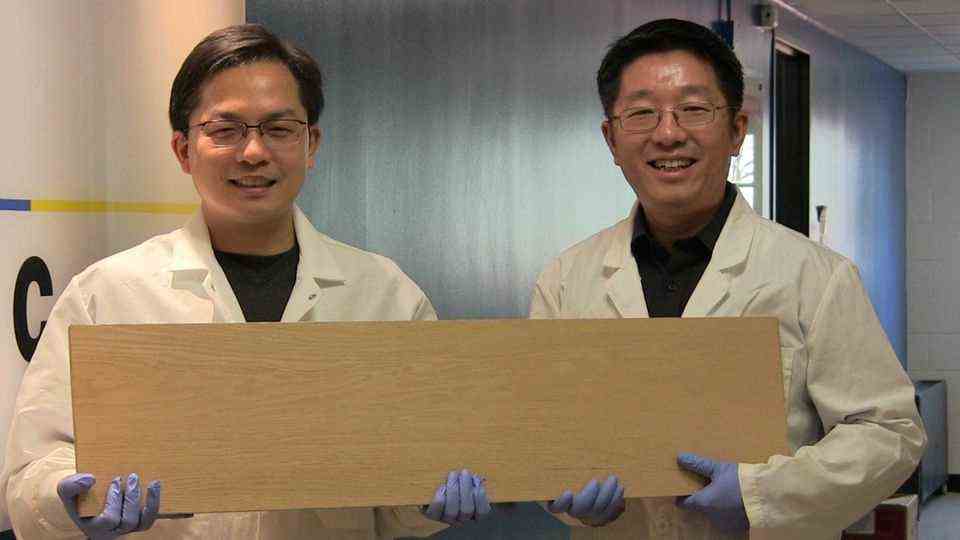

The idea is simple. Wood owes its strength to cellulose. It makes up 40 to 50 percent of the material and has a better strength-to-density ratio than many technical materials such as ceramics, metals and polymers. However, other components of the wood – hemicellulose and lignin – weaken the structure. The trick now is to remove these substances. “It’s a two-step process,” says the lead author of the study, Teng Li. “In the first step, we partially delignify the wood. Usually wood is very stiff, but after removing the lignin it becomes soft, flexible and somewhat mushy. Im second step we do a hot press by applying pressure and heat to the chemically treated wood to compact it and remove the water. “

A steak knife was then carved out of the resulting material. This has been oiled again to make it dishwasher safe. A steak could easily be cut through with a knife. The wooden knife is almost three times as sharp as a stainless steel table knife and 23 times harder than natural wood.

Objective of an industrial material

“The strength of a material is strongly influenced by the size and density of cavities, channels or depressions in the wood,” says Li. “The two-step process with which we process the natural wood significantly reduces or removes these things in the natural wood. Am In the end, these channels for the transport of water or other nutrients in the tree have almost disappeared. ” In addition, the team made nails out of the super wood, which are not only rustproof, but also as sharp as normal steel nails. The scientists hope that this new form of wood can become an environmentally friendly alternative to steel and ceramics, the manufacture of which requires a large amount of energy.

Source: Matter