Scientists are harnessing cells to create new types of materials that can grow, repair themselves, and even respond to their environment. These solid “artificial living materials” are created by embedding cells into an inanimate matrix that is shaped into the desired shape. Now researchers report in ACS Central Science , that they 3D printed a bioink using plant cells, which were then genetically modified to create programmable materials. Applications could one day include bioproduction and sustainable construction.

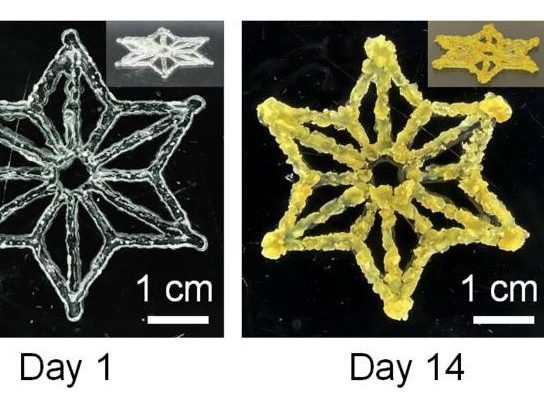

Between the first day (left) and the 14th day (right), the plant cells 3D printed in hydrogel grow and thrive into yellow clusters.

Adapted from ACS Central Science 2024, DOI: 10.1021/acscentsci.4c00338

Recently, researchers have developed living materials, relying primarily on bacterial and fungal cells as the living component. But the unique properties of plant cells have sparked enthusiasm for their use in artificial living plant materials (EPLM). However, the plant cell-based materials produced so far have had fairly simple structures and limited functionality. Ziyi Yu, Zhengao Di and colleagues set out to change this by creating intricately shaped EPLMs containing genetically engineered plant cells with customizable behaviors and capabilities.

The researchers mixed tobacco plant cells with gelatin and hydrogel microparticles that Agrobacterium tumefaciens contained, a bacterium commonly used to transfer DNA segments into plant genomes. This bioink mixture was then 3D printed on a flat plate or in a container filled with another gel to form shapes such as grids, snowflakes, leaves and spirals. The hydrogel in the printed materials was then cured with blue light, which hardened the structures. Over the next 48 hours, the bacteria in the EPLMs transferred DNA to the growing tobacco cells. The materials were then washed with antibiotics to kill the bacteria. In the following weeks, as the plant cells in the EPLMs grew and multiplied, they began to produce proteins dictated by the transferred DNA.

In this proof-of-concept study, the transferred DNA enabled tobacco plant cells to produce green fluorescent proteins, or betalins – red or yellow plant pigments valued as natural dyes and dietary supplements. By printing a leaf-shaped EPLM with two different bioinks – one producing a red pigment along the veins and the other a yellow pigment in the rest of the leaf – the researchers showed that their technique can create complex, spatially controlled and multifunctional structures. Such EPLMs, which combine the properties of living organisms with the stability and durability of non-living substances, could be used as cellular factories to produce plant metabolites or pharmaceutical proteins, or even in sustainable construction applications, the researchers said.

Note: This article was translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of breaking news. Since this article was translated using automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. You can find the original article in English here.