Jan Haupt descends the steps into the dry dock. Equipped with a clipboard, hammer, tape, flashlight and an ultrasonic measuring device, over the next few hours he will MS Utting investigate. More on exactly what he needs the tools for in a moment. The first thing that strikes you is that the ship is missing something crucial: water. the MS Utting is currently in the so-called dry dock of the Ammersee-Schifffahrt. This means that it is dry, to be precise standing on several large blocks. The water around has been pumped out so that the part of the ship that is normally below sea level is now accessible.

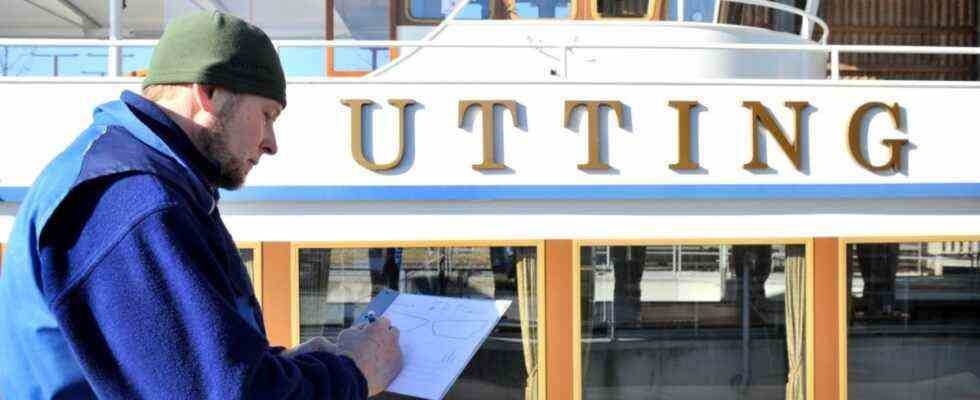

The 49-year-old Haupt with a trimmed beard, green cap and a precise look works for TÜV-Süd and today carries out an inspection for ships like the MS Utting due every five years. It is the first land survey for the ship, which has been sailing across Lake Ammer since 2017. Haupt says several times that “not much is to be expected” from this ship. The trained mechanical engineer is now concerned with examining the hull of the boat. The technology, such as the engine, is checked separately every two years during the so-called operational inspection. Haupt begins to walk the ship step by step from the outside, occasionally tapping the steel with his hammer, looking for dents and taking a close look at the welds. Normally he lights up ships for this, he says, but today the sun is shining on Lake Ammer and Haupt can do without an artificial light source – for now. The inspector discovers a small amount of corrosion, i.e. rust. He taps it with the hammer. If something were to fall out, that wouldn’t be good, but that’s not the case. According to Haupt, the spot is not a problem for the hull.

Jan Haupt from TÜV-Süd checks the hull of the MS Utting, which is in the dry dock.

(Photo: Nila Thiel)

He finds it somewhat unusual that the paint is clearly peeling off in some places. That shouldn’t be the case, but it’s not a safety problem, the expert assures, because the surface underneath is blank. It should be observed over the years. The manager of Ammersee-Schifffahrt, Florian Schmid, immediately assures that the responsible shipyard will touch up and replace the paint where necessary without any problems.

Haupt uses an ultrasonic measuring device to measure the steel thickness

Also the tape comes on the outside of the MS Utting for use. Of course, Haupt doesn’t try to fix the peeling paint with it, but uses it as a marker. A worker sands down the paintwork at the selected points so that Haupt can accurately measure the thickness of the wall. And this is where the ultrasonic measuring device comes into play. The steel thickness is shown in millimeters on the display when Haupt holds the end of a cable to the side of the boat. But first he applies a coupling agent, “like at the doctor’s,” he says. The result of the first measurement: just over six millimeters. main is satisfied. In advance it was calculated that the wall of the MS Utting should be at least 3.4 millimeters thick. Haupt is satisfied with the outside of the ship for the time being, later he will measure the wall thickness at the remaining points.

The steel thickness of the MS Utting is measured by Jan Haupt. Florian Schmid, manager of Ammersee-Schifffahrt, observes the process.

(Photo: Nila Thiel)

According to Haupt, TÜV-Süd-Industrieservice is the only company that can carry out TÜV inspections on passenger ships on Bavarian lakes. Haupt has already examined three such ships this year. There are only about a handful of people like him in the area in Bavaria, but that’s enough. The 49-year-old has been inspecting ships for around ten years and was specially trained for this, as he explains. At the same time, he also checks steam boiler systems. Haupt used to examine new fuel rods for nuclear power plants. It’s a reassuring feeling when a man with so much experience now checks the ship for the trip across Lake Ammer.

A little later in the year, sports boats are still on Haupt’s to-do list. “That’s a lot,” he says. That’s why there are collection dates from May on, each with twelve to 15 boats and also several responsible colleagues. Finally, Haupt also reveals a detail that one would probably not have expected from someone who is professionally involved with ships: he gets seasick easily.

For the TÜV inspection, Jan Haupt also checks the steel quality inside the ship, here in the tank room.

(Photo: Nila Thiel)

On this day, Haupt is lucky in that respect, because the MS Utting does not rock the waves as he continues his investigation inside the ship. The wall is also checked from this side and Haupt still needs a flashlight after all. In some places, plates have to be lifted up so that he can shine into hidden corners. Among other things, Haupt checks the floor in the engine room. “Everything clean and shiny.”

Finally, the man with the clipboard draws a conclusion: the result is positive – as expected. There are “as far as there are no abnormalities” and no conditions. He only makes one recommendation, namely to observe the areas where the paint has splintered. After the TÜV-Süd visit has been completed, Haupt will also send the result of his report to the responsible district office. A few weeks before the start of the season, so works manager Schmid plans, the MS Utting then finally released back into the Ammersee after their time in the dry dock.